One of the many things that makes DX Engineering unique is its commitment to making high-quality products from smaller amateur radio manufacturers available to operators worldwide. While the giants of the ham radio community are well represented at DX Engineering, up-and-coming producers of station-enhancing gear find a welcome spot at the table among more familiar names.

After 25 years of serving the needs of amateur radio operators, DX Engineering has grown along with companies that, like itself, started small but had big ideas about how to make an impact for operators who demanded smartly designed station solutions that were built to last.

With this in mind, OnAllBands is excited to showcase products from Rocket Machine Worx, one of the latest additions to the more than 175 manufacturers whose products you’ll find at DX Engineering. We stopped by the Rocket Machine Worx booth at 2025 Dayton Hamvention® to visit with the Millen, Georgia (population around 3,000) company operated by husband-and-wife Navy veterans and Extra class licensees Jason Welsh, KC2CIX, and Lisa Welsh, KI6HHY.

They both embrace the challenges of designing and machining better products from concept stage to finished piece.

“It all started because we wanted to start a business of our own and saw a need in the market,” Lisa told OnAllBands, adding that they’re always listening to the needs of the ham community and thinking up ways to meet those needs. “We are coming up with new products all the time.”

Read their bios here, along with a story about how the company shares its name with a very special dog they adopted while stationed at Misawa Air Force Base in Japan.

Watch Tim Duffy, K3LR, DX Engineering CEO, interview Jason, KC2CIX, in the video below:

Here’s what you’ll currently find from Rocket Machine Worx at DX Engineering:

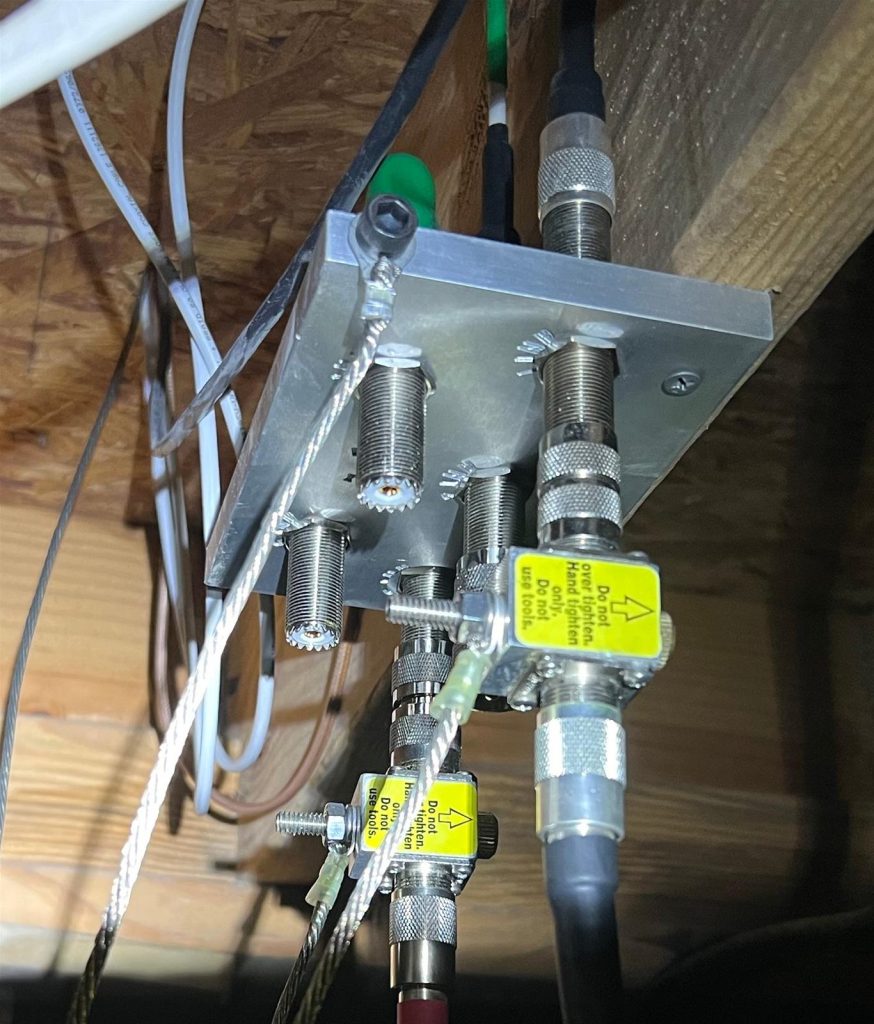

MidPatch Bulkhead Coaxial Connector Panel

Looking for flexible mounting options to cleanly and professionally install and manage coaxial cables in your station? Here’s a well-built solution. This 6″ x 6″ panel is precision-engineered and CNC-machined from ½-inch-thick 6061-T6 aluminum. It features seven 5/8-24″ CNC-threaded holes (no through-holes here, folks!), designed to accept the included high-quality SO-239 bulkhead connectors.

“All of our products are machined out of quality aluminum,” Lisa, KI6HHY, noted.

Additionally, the MidPatch can function as a manual coax switch. To use it this way, connect a jumper from your transceiver to the rear of the center connector. Then connect another jumper from the front of the center connector to the antenna of your choice.

Mounting options include four 5/8-16″ threaded holes located on all four edges of the panel for mounting to a bracket. Additionally, four holes on the face of the panel accept machine screws with stand-offs or #6 drywall screws (mounting hardware not included). The MidPatch can be mounted directly to rafters, floor joists, or into any properly sized enclosure.

What do hams say about the Rocket Machine Worx MidPatch?

Five Stars: I needed a panel that would work with my three antennas. I had been using two antenna switches but that was confusing at times. This way I know what antenna goes to what radio.

John, DX Engineering Customer

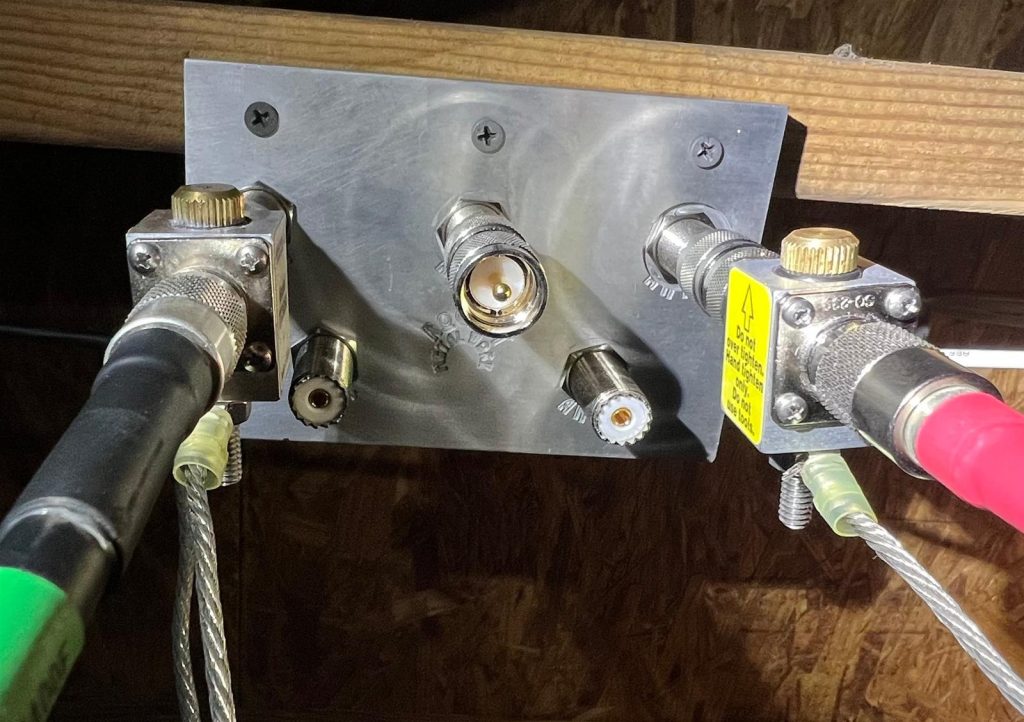

MiniPatch Bulkhead Coaxial Connector Panel

Featuring the same quality materials, high construction standards, and functionality of the MidPatch, this 6″ x 3.5″ panel features five 5/8-24″ CNC-threaded holes that accept the included SO-239 bulkhead connectors. Mounting options include 5/8-16″ threaded holes located on two edges of the panel for mounting to a bracket and three holes on the face of the panel. Its compact size makes it perfect for your go bag, POTA kit, or desk hutch in the shack.

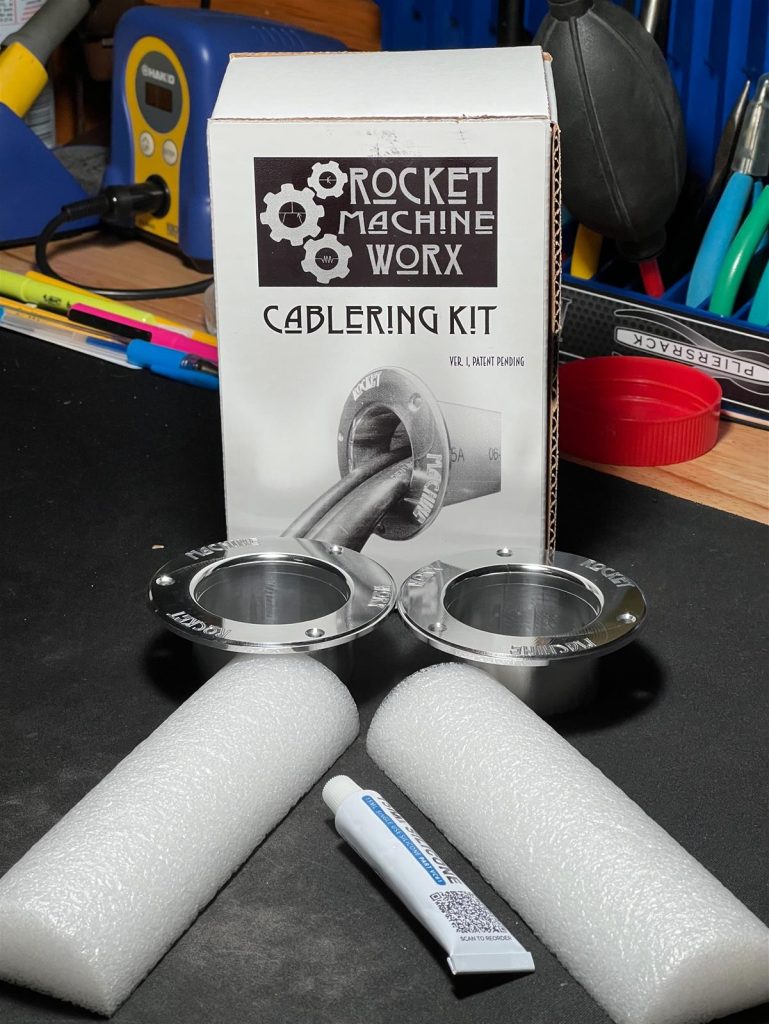

CableRing Cable Feedthrough Kit

The CableRing Cable Feedthrough solves the common issue of getting coax cables into the shack. With its professional-grade construction and ease of use, the CableRing provides an effective and great-looking cable management solution.

This innovative pass-through is compatible with standard two-inch PVC pipe (not included) and provides a precision press fit into the pipe, ensuring your cables are neatly routed through any surface, whether it’s a floor, wall, or even a spaceship bulkhead. Simply use round insulation combined with steel wool to keep out critters and maintain a clean installation. Features include:

- Precision CNC Machining: Crafted from 6061-T6 aluminum, the CableRing offers durability and a sleek finish.

- Perfect Fit: The large 3.120-inch diameter of the CableRing covers a 2-3/8-inch drilled hole, ensuring a clean installation.

- Smooth Cable Routing: Both inner edges are radiused, allowing cables to glide effortlessly through, even with connectors attached.

Note: Depending on your installation requirements, you will need to supply the necessary mounting hardware and two-inch schedule 40 PVC.

CableRings are also available separately.

The post New Ham Radio Manufacturer Spotlight: Rocket Machine Worx appeared first on OnAllBands.